The Pentagon has known for years that a significant number of the replacement parts it buys for its missile guidance and satellite systems contain substandard counterfeit microchips. But finding these fakes—as they make their way through a complex global supply chain of fabrication facilities, assembly plants and parts distributors—can be like searching for a needle in a haystack (made entirely of other needles). The military estimates that up to 15 percent of all spare and replacement parts for its weapons, vehicles and other equipment are counterfeit, making them vulnerable to dangerous malfunctions.

Counterfeit microchips—integrated circuits in particular—have turned up in replacement parts for U.S. Missile Defense Agency mission computers (pdf), ship-based aviation antenna equipment and in helicopter night-vision systems. Between November 2007 and May 2010 alone, U.S. Customs officials seized 5.6 million counterfeit microchips destined for military contractors and the commercial aviation industry, and the problem has only grown since then.

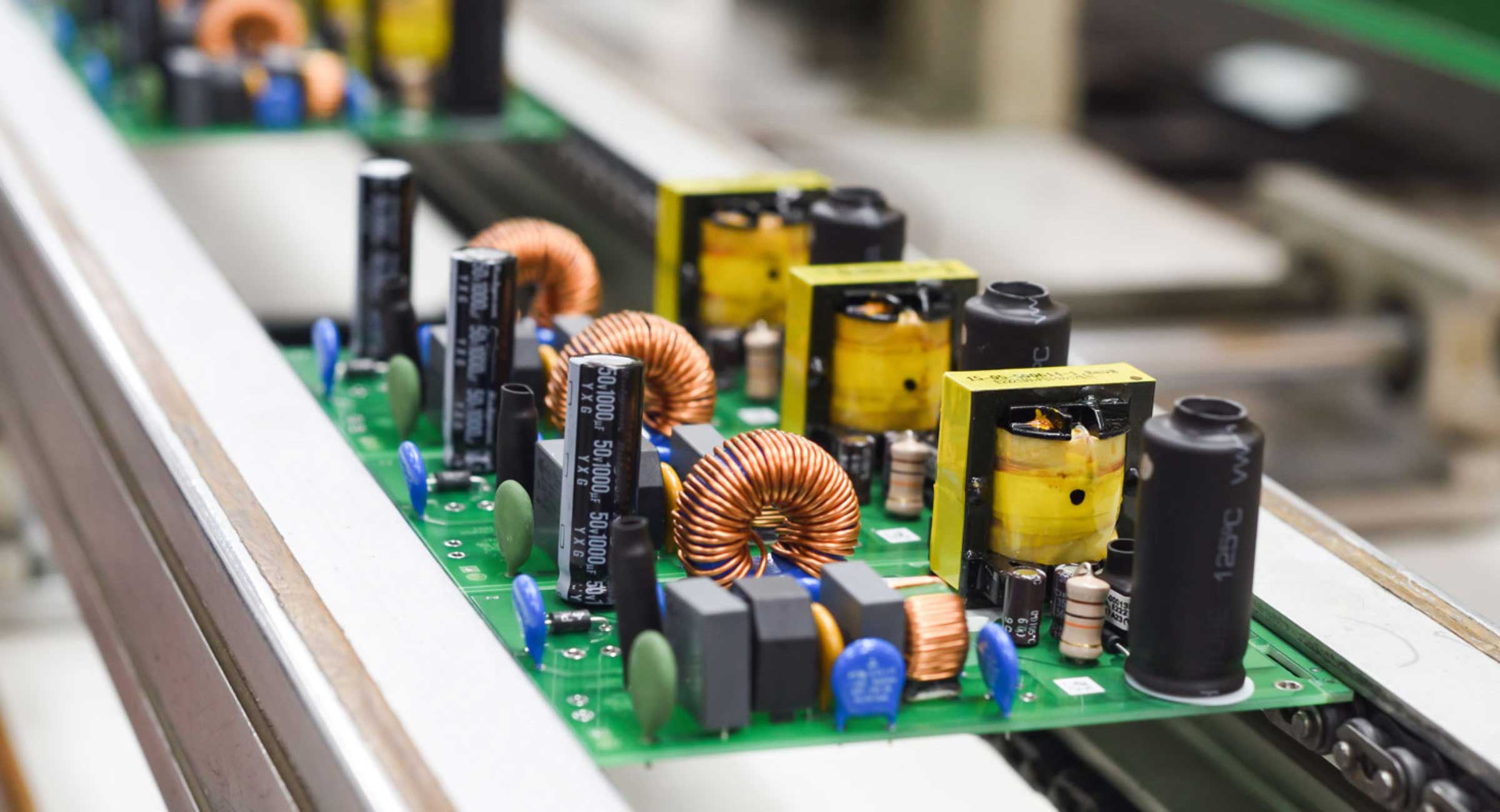

Given that integrated circuits serve as the brains for so much of the military’s technology—and the failure of even a single one can cause serious problems—the U.S. Department of Defense’s research arm has launched a counterattack against counterfeiters. Its Defense Advanced Research Projects Agency (DARPA) is now leading an effort to create microscopic identification tags called “dielets” that legitimate chipmakers can implant in their circuits as they are assembled. The dielets—which DARPA also calls “chiplets”—will enable the companies that install those microchips in circuit boards and other components to check whether the integrated circuits have been altered or substituted with fakes.

Reports of catastrophic failures caused by such parts are hard to come by, but officials are obviously concerned. In December 2015 federal agents arrested three Chinese nationals for, among other things, selling 45 counterfeit Intel microchips to an undercover agent with the understanding the chips would be headed to the U.S. Navy for a project involving submarines. One of the men arrested—Jiang Guanghou Yan—had also asked the undercover agent to get him 22 military-grade Xilinx Corp. microchips—worth $37,00 apiece—for illegal export to China. “Military grade” means the electrical components are designed specifically to withstand prolonged exposure to extreme temperatures and radiation. When the agent advised Yan they would have to be stolen from a U.S. Navy base, Yan offered to cover up the crime by providing fakes to replace the stolen chips.

“If [those counterfeit chips had been] installed in a missile’s guidance system, such missile would either not function at all or would likely not proceed to its intended target, and would likely strike a completely unintended destination,” Keith Avery, a senior engineer at the U.S. Air Force Research Laboratory, testified in an affidavit used to determine the sentences of the convicted counterfeiters in June 2016.

The dielets that DARPA is developing as part of its Supply Chain Hardware for Electronics Defense (SHIELD) program are essentially microscopic tags embedded in each integrated circuit. An integrated circuit is made up of large numbers of transistors and other tiny electrical components arranged to perform a specific task—signal switching or amplification, for example—and packaged together into a chip that plugs into a larger circuit board used to control a particular electronic device. Under DARPA’s plan the integrated circuit’s manufacturer would affix a dielet inside the case that encloses the integrated circuit. Each chiplet will itself have up to 100,000 transistors and include a two-way radio, data encryption engine and way to detect tampering—all while consuming under 50 microwatts (50 millionths of a watt) and costing less than one penny each.

Identifying information on each dielet would be read using a penlike probe plugged into a smartphone. Rather than containing its own power source a dielet would be inductively powered by the probe, which would communicate via radio frequency signals when placed within a half millimeter of the chiplet. The probe would relay encrypted information to an app on the smartphone, which would then connect via the internet with a database to confirm the dielet’s serial number. It would also read the dielet’s GPS location to make sure the chip is where it is supposed to be as well as check other unique characteristics. If the probe gets no response or if there are inconsistencies between the chip’s data and that stored in the integrated circuit inventory database—along with any device in which it might be installed—the circuit would be put aside for further inspection.

To prevent counterfeiters from easily discovering these implants, they will be about 10 microns thick and no larger than 100 microns per side—roughly the size of the head on the statue inside the Lincoln Memorial depicted on the “tails” side of a penny, according to DARPA. The dielets’ tiny size helps them meet several DARPA requirements—for example, they should be too fragile to remove from their integrated circuits (to be reverse-engineered and themselves counterfeited) without being damaged.

Integrated circuits are especially difficult to protect from counterfeiting because they might come from an overseas manufacturer and be resold by several subcontractors before a large military supplier like Lockheed Martin or Boeing embeds them in technology that it sells to the U.S. government. The global growth of the supply chain that lets electronics manufacturers tap less-expensive suppliers in China, Japan, Singapore, South Korea and Taiwan has proved very difficult to police. Electronic waste from the U.S. is another key contributor to counterfeit integrated circuits, as trashed circuit boards from computers discarded in some countries are often taken apart, refurbished, relabeled, repackaged and resold as new to electronics manufacturers.

“The net of the thing is that we don’t have as much control over the authenticity and integrity of the systems we use,” says Kerry Bernstein, program manager of DARPA’s Microsystems Technology Office and head of the four-year, $50-million SHIELD program overseeing dielet development. “The counterfeit problem appears at first glance to be intractable.”

Former Pres. Barack Obama stepped up efforts to crack down on counterfeiting in late 2011 when he signed the National Defense Authorization Act, which required the secretary of defense to come up with a plan to cut down on the military’s use of counterfeit parts. The Defense Department has since been testing and using special inks laden with plant DNA to uniquely mark and later identify electronic components in its supply chain.

DARPA launched SHIELD as a more sophisticated approach that could provide immediate identification of knockoff electrical components. The agency is managing the development effort but much of the work is being done by Northrop Grumman Mission Systems, SRI International and a number of subcontractors. The dielets’ microscopic size keeps their cost down, as millions of them can be made from a single silicon wafer. Northrop and SRI have already demonstrated prototype dielets to DARPA that meet most SHIELD criteria, Bernstein says. The Pentagon plans to test the mettle of these chiplet ID tags by inserting them into a test supply chain by 2019—the next salvo in the military’s battle against counterfeiters and knockoffs that potentially place their personnel and the public in harm’s way.